Discover the Beauty of Vitrofusion Art: A Complete Guide

(You can buy this in our page or you can go to Etsy)

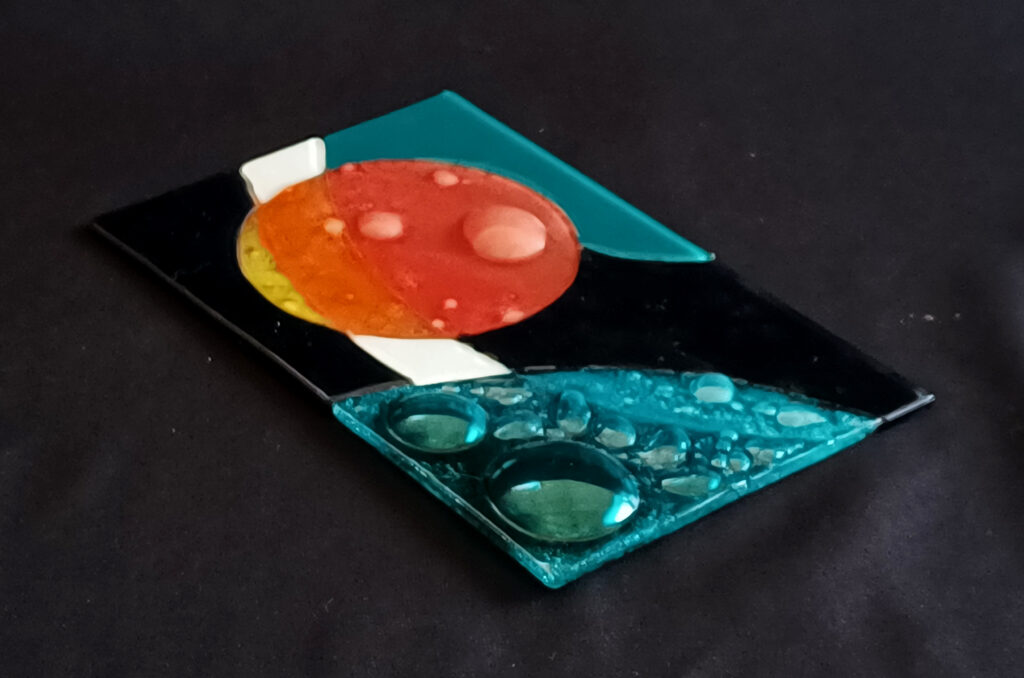

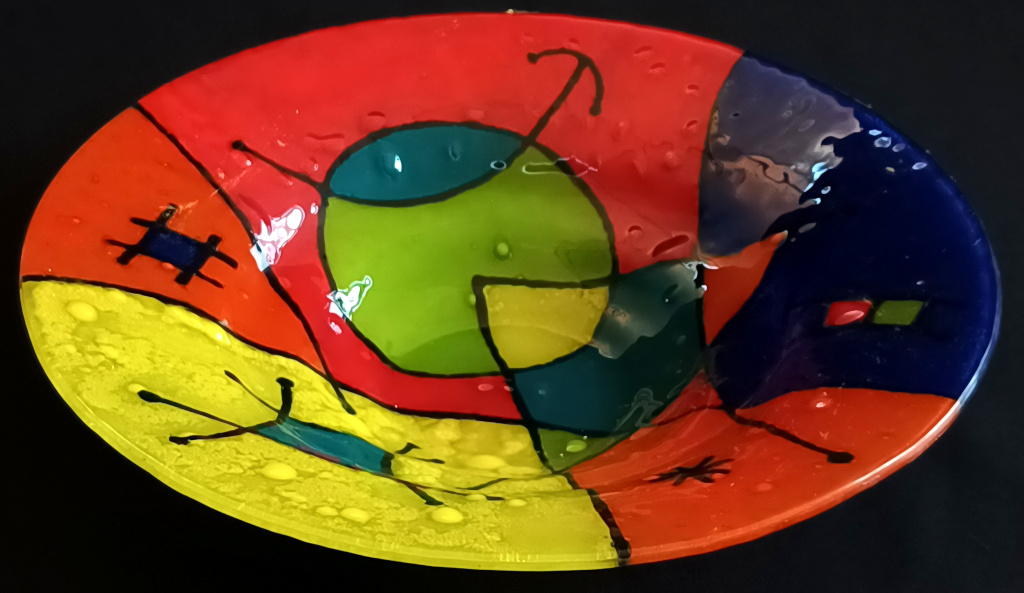

Vitrofusion art blends science, creativity, and precise technique into one captivating form. It involves fusing layers of glass at high temperatures to create decorative or functional pieces that catch light and color in unique ways. Vitrofusion art allows anyone to transform simple glass into designs that highlight beauty, texture, and craftsmanship.

This form of art appeals to those who appreciate both structure and imagination. Artists explore patterns, transparency, and movement by controlling how glass melts and bonds. Whether used for sculptures, jewelry, or wall panels, each piece reveals skill in handling fragile materials with care.

Understanding vitrofusion art begins with learning its basic methods, tools, and materials. From preparing glass to designing layered compositions, each step opens new creative possibilities. The process encourages patience and experimentation that often leads to striking and personal works of art.

What Is Vitrofusion Art?

Vitrofusion art brings together science and craftsmanship to create images or shapes within layers of glass that melt and fuse inside a high-temperature kiln. This process combines color, heat, and time to form durable, decorative works that balance artistic design with material precision. It often reflects both cultural traditions and modern experimentation in the field of glass art.

Origins and History of Vitrofusion

Vitrofusion has roots in ancient glass-working techniques that date back thousands of years. Early civilizations in Egypt and Mesopotamia developed methods of melting glass to form beads and small vessels. These early practices laid the foundation for later techniques focused on glass fusing.

Modern vitrofusion developed in the 20th century, when artists and scientists began exploring glass behavior under controlled heat. Innovations in kiln technology made it easier to experiment with glass layers, textures, and colors.

By the late 1900s, workshops in Europe and the Americas started formal training in glass fusion methods. Today, vitrofusion is seen as both an artistic craft and a scientific exploration of how materials behave at high temperatures.

Defining Glass Fusing and Fused Glass Art

Glass fusing involves heating multiple pieces of glass until they melt and bond as one solid piece. This process usually happens in a kiln set between 700°C and 850°C depending on the glass type. Each layer interacts to create subtle blends, bubbles, or transparent sections.

The resulting materials are called fused glass or kiln-formed glass. Artists may shape them into panels, jewelry, plates, or sculptures.

A glass fusing project often includes:

- Cutting and layering compatible glass pieces

- Adding elements like metal foils or colored powders

- Heating in stages: fuse, slump, and anneal

While it shares some traits with stained glass, fused glass does not rely on metal frameworks to hold pieces together. Instead, the fusion itself forms a single, seamless body of glass.

How Vitrofusion Differs from Other Glass Art Forms

Vitrofusion differs mainly in process and surface quality. Techniques such as stained glass or glass blowing depend on joining cooled pieces or shaping molten material, while vitrofusion shapes solid sheets through heat alone.

Unlike blown glass, which involves air expansion, vitrofusion focuses on controlled melting for flat or layered designs. It produces textures difficult to achieve with other glass art methods, combining transparency with depth.

In kiln-formed glass, color gradients appear where overlapping layers merge. This lets artists design complex patterns that capture light differently across the surface. Many prefer vitrofusion for wall art, architectural panels, and unique home decor because of its versatility in both form and color.

(You can buy this in our page or you can go to Etsy)

Essential Techniques and Tools

Vitrofusion combines heat, precision, and careful preparation to create fused glass objects of lasting quality. Artists depend on reliable methods, specialized tools, and safe practices to shape and finish each piece correctly.

Fundamental Vitrofusion Methods

The main vitrofusion processes are fusing, slumping, and casting. Fusing joins multiple layers of glass at about 750–850°C until they bond into a single sheet. Slumping shapes the fused piece by heating it on a mold, allowing gravity to help it take form. Casting involves melting glass into a mold to produce solid or textured designs.

Each stage requires precise control of kiln temperature and timing. Artists often record their kiln schedules to ensure consistency between creations. Cooling, or annealing, is essential—it relieves internal stress in the glass and prevents cracking.

After heating, cold working refines surfaces through grinding, sandblasting, or polishing. These steps smooth edges, correct imperfections, and add detail without reheating the glass. By mastering these basic methods, artists can achieve strong, even finishes and predictable results in every project.

Key Tools for Glass Fusing

Vitrofusion depends on equipment designed to manage heat and handle fragile materials safely. The kiln is the core tool, often lined with kiln shelves or coated with release agents to keep projects from sticking. Glass cutters and running pliers help shape glass pieces with precision before firing.

Artists also use glass rods, stringers, and frits to add color, depth, or texture. A small worktable with cutting mats keeps pieces aligned and reduces waste. Measuring tools, such as metal rulers and templates, ensure proper symmetry and fit when layering glass.

A typical setup might include:

| Tool | Purpose |

|---|---|

| Kiln | Heating and fusing glass |

| Kiln Shelf | Supports and protects pieces during firing |

| Running Pliers | Break scored glass cleanly |

| Grinder | Refines edges and shapes |

These tools make it possible to move from raw glass to a polished art form with control and efficiency.

Safety Practices in the Studio

Working with heated materials and sharp edges demands careful attention to safety. Artists should always wear safety goggles and heat-resistant gloves when cutting or handling glass. Closed-toe shoes and long sleeves protect against shards and burns.

Proper ventilation is vital when using adhesives, molds, or kiln coatings that may release fumes during firing. Keeping tools clean and surfaces organized helps prevent accidents. Fire extinguishers and first-aid supplies should remain within reach.

When operating kilns, users should monitor temperature readings closely and avoid quick openings during the cooling phase. Storing glass upright and separated by color or thickness also reduces breakage. By following these precautions, artists maintain both their health and the integrity of their work environment.

Materials and Preparation

Creating art through vitrofusion requires careful selection of glass materials and precise preparation before the firing process. Durable and well-matched glass ensures that the final piece fuses evenly and maintains its shape. Each type of material contributes differently to color, texture, and clarity.

Selecting Fusible Glass

Artists use fusible glass designed to melt and bond at specific temperatures without distorting or cracking. Common brands label their products with a COE (Coefficient of Expansion) value, helping artists choose compatible sheets. Most use glass rated at COE 90 or COE 96 because these fuse smoothly and are easy to cut.

Fusible glass often comes in different forms—transparent, opalescent, or streaky—to control how light moves through the finished artwork. Many artists also recycle leftover stained glass if it matches the right COE.

When preparing, it helps to clean all glass pieces with alcohol or glass cleaner to remove residue that can cause bubbles. A clean surface allows the fusion process to produce a polished and clear result.

Understanding COE and Glass Compatibility

The Coefficient of Expansion (COE) measures how much glass expands or contracts when heated and cooled. If two pieces with different COEs fuse together, they cool at different rates and may develop stress cracks. This can ruin the appearance and structure of the piece.

To prevent this, artists test compatibility by firing small fused samples. If the bond remains stress‑free after cooling, the glasses are compatible. Studio charts often list the COEs of popular brands for easy reference, such as Bullseye (COE 90) and Spectrum (COE 96).

| Common COE | Type or Brand | Notes |

|---|---|---|

| 90 | Bullseye Glass | Smooth fusing, vivid color |

| 96 | Spectrum System 96 | Easier cutting, wide color range |

Even slight variations can cause problems, so accuracy is essential in every stage of preparation.

Using Frit, Glass Rods, and Other Materials

Frit, glass rods, and stringers add decoration and texture. Frit comes in particle sizes from powder to coarse chips. Artists sprinkle or layer it to create shading and patterns. Glass rods and stringers can be bent or layered to form linear designs.

Small details such as metal foils, enamels, or glass confetti can enhance effects, but all materials must share the same COE as the base glass. Kiln shelves should be lined with kiln wash or fiber paper to stop the fused glass from sticking.

A simple preparation checklist includes:

- Cleaning and drying all components

- Checking for COE compatibility

- Arranging the design on the base sheet before firing

Proper preparation gives the artist greater control over shape, color, and balance in each fused piece.

Creative Applications and Inspiring Projects

(You can buy this in our page or you can go to Etsy)

, also known as fused glass art, blends color, texture, and heat to produce glass pieces ranging from functional designs to fine art. Artists shape their work through specific firing methods, post-firing techniques, and careful finishing that enhance both durability and appearance.

Popular Types of Fused Glass Art

Fused glass artists create decorative panels, jewelry, tableware, and sculptural pieces. Wall panels and trays often use layered transparent and opaque glass sheets for depth and color mixing. Jewelry makers focus on small kiln-fired segments with metallic or dichroic coatings that reflect light in vivid tones.

Functional works, such as dishes and bowls, combine both artistic and practical goals. Artists fuse flat sheets, then heat the piece again for slumping over molds that shape it into smooth, curved forms. Studio projects may include window inserts, coasters, or light fixtures that catch natural or artificial light. Each type requires controlled heating and cooling schedules to prevent stress cracks and maintain polish.

Artistic Techniques for Unique Results

Creating fused glass art involves a sequence of cutting, layering, fusing, slumping, and shaping. Artists lay out glass pieces on a kiln shelf lined with shelf paper or fiber to prevent sticking. Temperature control is key—too rapid a rise or drop can cause uneven fusion or breakage.

Some artists experiment with powdered glass (frit) for coloring and texturing. Others include small design elements like stringers or confetti for finer detail. After firing, cold working techniques—such as grinding, sandblasting, or polishing—refine edges and surfaces to the desired finish.

Different firing schedules achieve distinct visual effects:

| Technique | Result | Example Use |

|---|---|---|

| Full fuse | Smooth, even surface | Jewelry, panels |

| Tack fuse | Slightly raised textures | Decorative art |

| Slump | Forming curved shapes | Bowls, platters |

Display, Care, and Finishing Tips

Finished glass art needs thoughtful display and maintenance. A stable stand or wall mount keeps larger panels secure, while smaller items often look best on lighted shelves. Positioning under natural light enhances color reflections and internal textures.

Proper cleaning avoids damage. Artists recommend wiping pieces with a soft cloth and mild detergent, avoiding abrasives. Kiln-fired finishes resist fading but can still scratch if rubbed on hard surfaces.

For long-term preservation, collectors often store glass upright with padding between pieces. Artists apply smooth edges and polish using cold working tools to improve appearance and handling safety. Finishing touches, like applying clear coatings or metal fixtures, can highlight the craftsmanship while protecting the surface from wear.